"*" indicates required fields

Seyntex: faultless assembly of police clothing

The customer

The Belgian firm Seyntex is a leading manufacturer of protective clothing and equipment. Among other things, the company produces combat clothing, bulletproof vests and sleeping bags for defence authorities of more than 20 countries worldwide.

The challenge

Seyntex won an international tender for the production of tens of thousands of bulletproof vests, lap belts and shoulder pads in various sizes, where each component of each set had to be uniquely identifiable by using RFID technology.

To enable RFID identification and tracking, every single component of the clothing had to be equipped with a robust textile tag, programmed and secured according to specific requirements.

Seyntex was looking for a scalable tracking solution that could be rolled out quickly.

The solution

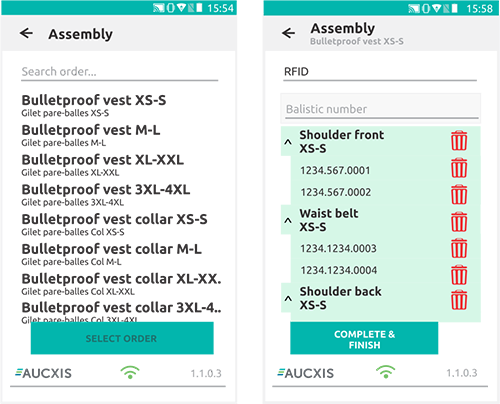

Due to the tight deadline and the huge number of tags to be programmed (260,000 pieces), Aucxis proposed to implement its RFID solution consisting of RFID textile tags, an RFID programming station, RFID handhelds and the standard POLARIS Asset Management Software.

Each RFID tag links a component or set to a unique ID number which enables identification and verification through RFID handhelds.

Step 1: integration of the tag numbers in POLARIS

Seyntex provided a data list with the number of pieces needed for each product. Using this list, Aucxis integrated the requested tag numbers into the POLARIS Asset Management software via Excel.

Step 2: programming the RFID tags

Since the tags had to be programmed one by one, we made a programming station – RFID reader and antenna – with a smooth surface enabling the tags to pass very quickly.

Step 3: sewing in tags and checking

To check whether the right tag goes into the right component, employees use the POLARIS app running on an RFID handheld. They then sew the tags into the components and assemble the semi-finished products, without the bulletproof parts.

When finished, the assembly is scanned with the RFID handheld. If all components match, the product is validated.

Step 4: finishing products and checking

The bulletproof parts are added to the assemblies. Again, employees use the POLARIS app to verify that the right tag goes into the right (bulletproof) part. Validation is again done by using an RFID handheld.

The result

- More accurate than the naked eye: every finished product is guaranteed to consist of the right components in the right size.

- Errors are prevented by the additional quality control during the production process.

- Tracking of every component of every set throughout production and its entire lifetime.

- Reduced pressure on the staff and increased end-customer satisfaction thanks to the flexible and scalable solution that can be tailored to customer needs.

- Automatic reporting: overviews and reports can be conveniently accessed via the POLARIS web interface.