"*" indicates required fields

Safetybloc: tracing of safety barriers

The customer

The company Safetybloc produces and rents concrete safety barriers which are placed throughout the Belgian road network. These safety barriers are used to guide the traffic in the right direction during road works. Safetybloc was established by Wim Gilles, who is also manager of WG Aannemingen, a company that during many years organised the placing of safety blocs until it was decided to develop one’s own safety barrier that would offer even more resistance and safety. The new product, which successfully passed the crash test, was called ‘Safety Bloc”. It received an European licence and BENOR certification.

The challenge

Safetybloc looked for a solution that would enable its staff to efficiently identify and geolocate each safety barrier and in this way obtain a clear overview of all safety barriers in use and those available for new projects.

The challenge for Aucxis and Qeos was to select the most appropriate RFID tag for the specific application and to develop a solution for a safe geolocation of each safety barrier and a clear stock management.

The solution

The concrete part of each safety barrier holds a notch in which an RFID card is attached using a powerful glue. The RFID card contains the unique identification code of the safety barrier in 3 ways: textual, in a QR code and as data stored in the RFID tag which is incorporated in the card.

The identification of the safety barrier can be effected in different ways so that reading of the code is assured regardless of the environmental conditions (e.g. passage too small for a vehicle).

- Scanning of the RFID tag

The RFID tags are scanned, via an antenna, by a reading system in the vehicle that drives along the safety barriers; the reading is quick and dynamic.

With a handheld RFID scanner the safety barriers can be manually scanned in places that are difficult to access.

- Scanning of the QR-code

Via the scanner of the board computer the QR code can be manually read in places that are difficult to access or where an RFID reading is not possible.

- Manual input of the ID number

When none of the methods mentioned above can be used, the staff will manually input the ID code which is printed on the RFID card.

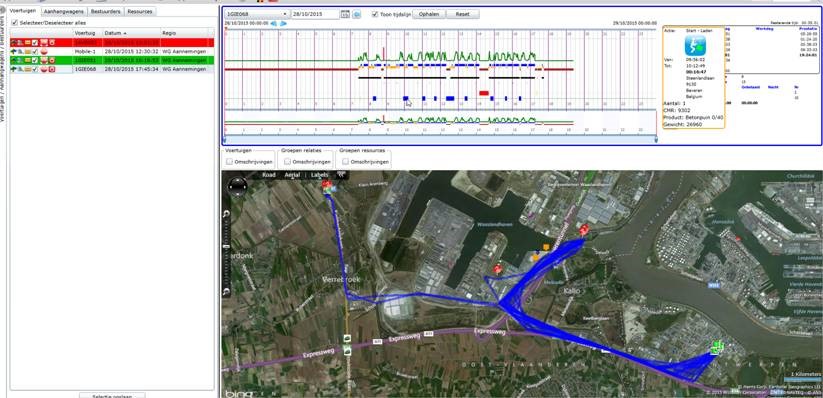

Real-time management system

Management of the mobile staff

Using the board computer, it is possible to:

- send orders to the chauffeurs (dynamic management per order type: placement/removal);

- send the addresses via POI (accurate identification of access to the road work site – prevents loss of time).

Stock management

- The read safety barriers are shown on a map.

- In the management and follow-up of the status of the stored safety barriers, it is possible to include pictures of damaged barriers (geolocated information in real time) which offers an important form of evidence.

Administrative management

- The identification and visual display of the stock available for new projects enables the staff to work faster.

- It is possible to register an electronic signature using the board computer.

- The delivery notes can be printed in the vehicle.

The result

- Safetybloc now has a real-time, accurate overview of the number of blocs and their location.

- The RFID identification system generates an enormous timesaving.

- The efficient management system fully meets the specific needs of the company’s business activity.