"*" indicates required fields

Bekina Boots: tracing of professional boots from production to after-sales

The customer

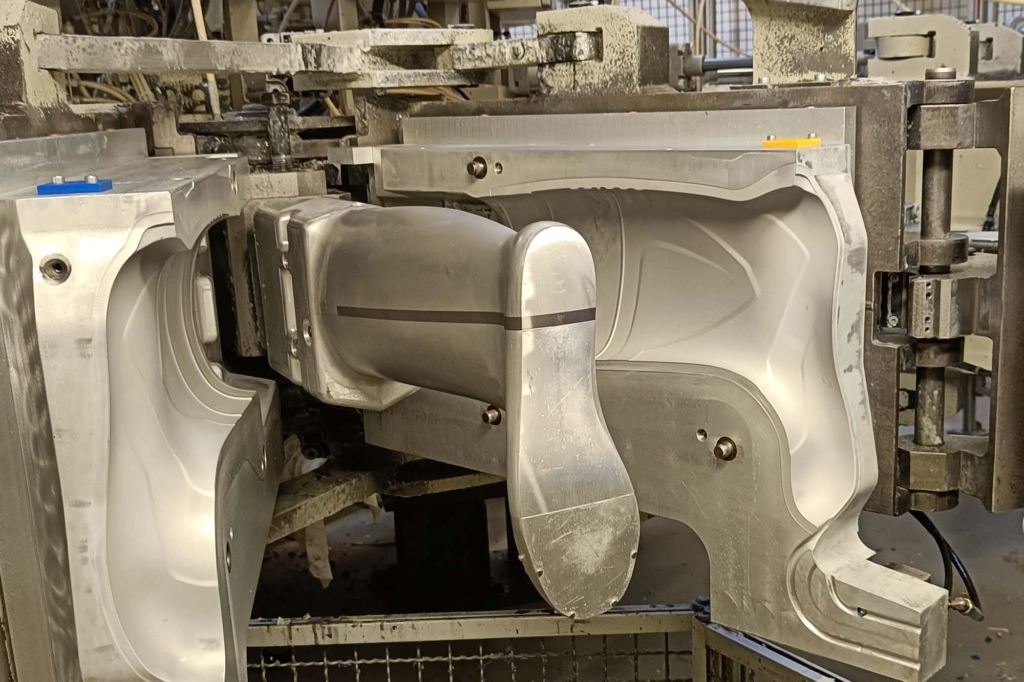

The Belgian boot manufacturer Bekina Boots is a joint market leader in the development and production of durable and qualitative polyurethane (PU) safety boots. Today the firm markets its professional boots – composed of the light, strong synthetic material polyurethane (PU) – in 58 countries worldwide and in a wide range of sectors such as agriculture, the fishing industry, construction and of course the food industry.

The challenge

From its drive for innovation and customer-friendliness, Bekina Boots was looking for a tracing solution to further finetune its internal logistic process. Previously, the safety boots were identifiable per unique SKU via barcode but the intention is that every boot is uniquely traceable until it arrives at the end customer.

With unique identification and tracing, Bekina Boots wants to map the entire life cycle of the safety boots, which will enable them to thoroughly analyse several parameters of the work boots and to aim for further quality improvement.

the production process.

located on which cart enabling the packing

manager to plan everything smoothly and

correctly.

The solution

A Proof of Concept made it possible to determine the appropriate RFID tag and the necessary detection points throughout the production process. Upon the selection of the tag, we needed to take into account several important parameters:

- The temperature of the synthetic material the boots are made of goes to 130°C during the production process.

- Every niche market Bekina Boots delivers to has its specific requirements in terms of safety, hygiene and wearing comfort. The boots are often worn in extreme working conditions, for example in a humid environment. The RFID tag needed to be integrated in such a way that it is performant in all sectors and situations without being a nuisance.

At the start of a production, an RFID label is programmed and printed for every boot. The tags are integrated in the boots in a way and at a location that the tag cannot be damaged during the life cycle of these very flexible boots. When integrating the tag, certain data points are captured and linked to Bekina Boot’s database thanks to the Aucxis middleware HERTZ.

For the further follow-up of the tagged boots throughout the production process, we provide RFID readers at the crucial logistic points.

The result

- Individually identifiable and traceable PU safety boots from the production process to the shipment.

- Flawless processing, labelling and shipment of the work boots

- Optimised customer service as a longterm investment.