"*" indicates required fields

Where are your goods located in your warehouse? Bye bye barcode, welcome RFID!

In production and warehouse environments, floor labels and covers with barcode are still regularly used to identify and localise goods. Preprogrammed RFID floor tags form a more durable, less expensive and safer alternative to guarantee accurate information about the logistics flow.

Barcodes used for localisation are stuck (labels) or mounted (covers with plexiglass) on the floor. The warehouse staff scan the barcode at the location where they drop off and pick up goods manually with a barcode scanner. The risk to forget scans or to perform incorrect scans is significant.

In larger warehouses where people are using transport equipment such as forklifts, AGVs and cranes, it is much more efficient to use passive RFID technology for the localisation of goods. The intensive actions to trace and process goods are completely automated. Thanks to the RFID Forklift solutions and a smart combination of RFID floor tags and RFID software for the reading, time-consuming procedures for checking off stock and other lists are a thing of the past.

Advantages of RFID floor tags versus barcode

More durable

They are not damaged when forklifts drive on them, last longer and do not require any maintenance.

Safer

Forklift drivers do not have to hold out their hand out of the forklift to scan their location.

Manual actions are avoided

No risk of wrong or forgotten scans.

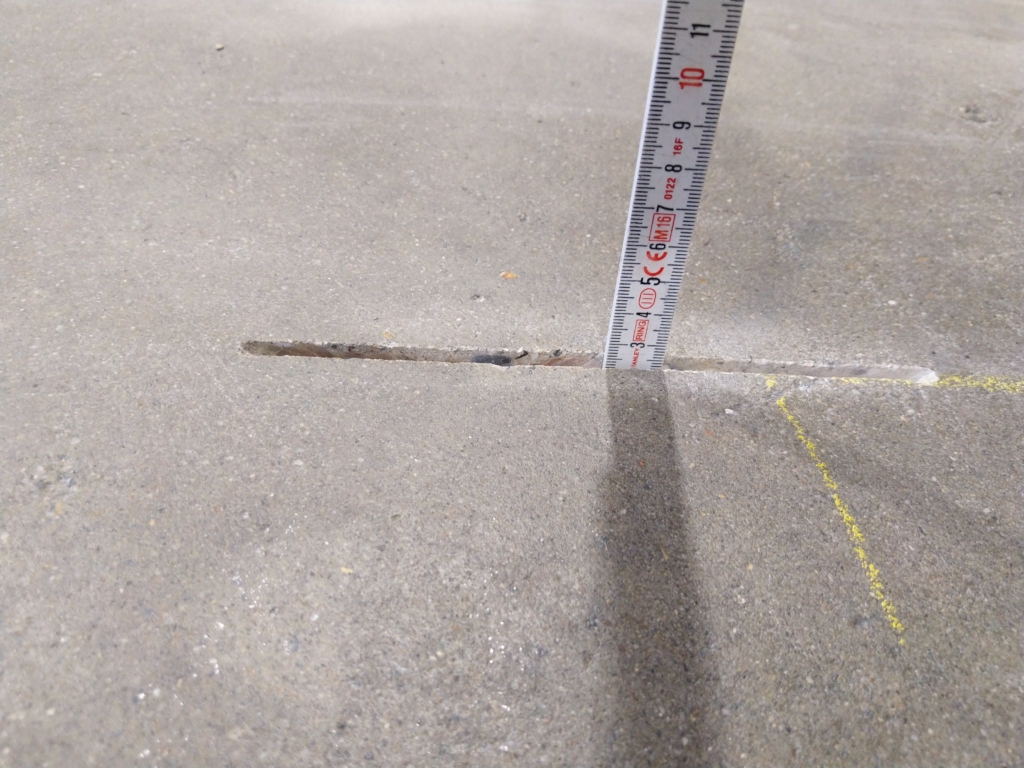

The preprogrammed RFID floor tags are incorporated at minimum depth in the warehouse floor at crucial places agreed with the customer. The floor tags are carefully sealed, avoiding irregularities on the floor; after installation, the functioning of the floor tag is tested with calibrated measuring equipment.

Endless combinations possible

If it is not possible or desired to install floor tags, a solution will be looked for, enabling the mounting of the RFID tags on racks or at other locations. A combination of floor tags and tags on racks is also possible to indicate zone passages, for example. Furthermore, the RFID tags are reprogrammable and very scalable making it easy to add extensions in the future.