"*" indicates required fields

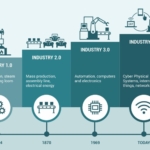

TREND: the transition to Industry 4.0

Industry 4.0 has been defined as a name for new technologies and concepts in industry. The term refers to the fourth industrial revolution. This intensive digitisation will result in new ways of manufacturing, new products, more efficient processes and new revenue models.

The so-called ‘smart factories’ with ‘smart products’ are introduced. In concrete terms, this means that machines are connected in an intelligent way with each other and that a smooth information flow is ensured. In the near future, technologies such as ‘The Internet of Things’ will enable industrial systems to adjust themselves autonomously by means of objective data.

In our daily lives, many devices are already smart. You can, for example, access and raise the temperature at your home remotely. A picture taken with your smartphone is immediately saved in the cloud. In short, digitisation is already strongly present in our lives.

‘Smart’ solutions on the industrial shop floor

Within the industry, this (r)evolution is less evident. In many companies, numerous old machines and computers are still used, most of which are not yet written off. Long-term investments make it impossible to switch to new machinery or technologies. This switch also needs to be phased over time, because manufacturing processes always need to continue to run around the clock.

But the industry cannot afford a standstill. People today live in the era of bol.com. As a result, they have everincreasing expectations and demands. That is why the industry needs to be adjusted to this.

The fourth industrial revolution, which is currently taking place, wishes to connect everything with each other and to allow data to flow. Manual retyping of data to other systems or programmes becomes something of the past. By making data available through a central system, transparency is achieved; information about machines, products, loads, … can be called up in real time. It will be possible to better manage the manufacturing process.

People, machines and algorithms have to learn how to work together in the labour market. Employees will be systematically redeployed; the boring routine tasks will eventually disappear while the demand for personal skills, such as creativity, will grow.